TOBI® Drive-System

Termékadatok

-

Overview

- Self-Hold-Effect leads to a slight clamping effect of the screw. This prevents the screw from falling out of the bit

- This facilitates exact placement and precise screw fastening, even in areas that are difficult to access

- The axial alignment of the screw in all assembly situations ensures easy application of the screw

- Utilization of the maximum available contact area leads to improved drive tool life

- Saving resources by eliminating vacuum technology

- More information on the official website: TOBI® Drive-System

Hotline

Applications Engineer

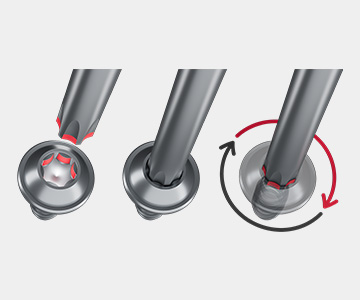

TOBI® Functionality

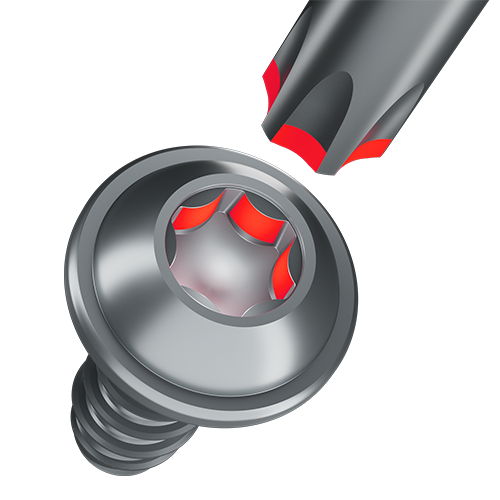

The TOBI® Drive System is a brand new drive concept. Thanks to the special design between drive and bit, three important requirements can be combined: The axial alignment of the system when inserting the bit into the screw head drive simplifies handling even in areas that are difficult to access. A contact surface between bit and drive that is up to 10 times larger ensures lower surface pressure and thus less wear on the tools.

Finally, the large concave and small convex radii inside the drive as well as a taper to the upper edge of the bit lead to a slight clamping effect of the screw so that it cannot fall out of the bit. This enables safe working in all positions, such as overhead assembly or when fastening components or parts in hard-to-reach areas – even in automated fastening processes.

Use in industrial assembly

The use of the TOBI® Drive-System prevents downtimes in fully or semi-automatic screw assembly. Worn bits cause enormous tool costs because they have to be replaced regularly. Every tool change means system downtime. The larger contact surface between TOBI® Drive and bit ensures a reduction of bit wear and a minimisation of tool change time.

The TOBI® Drive-System is optimized for manual assembly in industrial environments. It allows the worker to pick up screws with one hand, irrespective of the material being used. Since only one hand is needed for this, the other hand can be used for positioning or for holding the component. The axial alignment of the screw in all assembly situations ensures easy application of the screw.

Elimination of expensive vacuum technology

The vacuum technology previously used in assembly consists of a vacuum generator and a vacuum sleeve attached to the fastening system. This high-precision sleeve must be specially manufactured for each screw type and screw dimension, as it encloses the screw above the top of the head, creating a vacuum that holds the screw in the nosepiece. This technology is slow, energy-intensive and has only limited process reliability, as the suction and holding of the screw via a vacuum is very sensitive.

The TOBI® Drive-System does not require any complex system technology. Due to the self-holding effect, this innovative drive system also holds screws made of non-ferrous metals (e.g. stainless steel, titanium or aluminum) securely in all positions. This leads to significant cost and time savings and to a reduction of the CO2 footprint.

TOBI® is a registered trademark of bogenus GmbH

![[VBT_EVO_PT].png](/medias/sys_master/products/products/h0d/h92/9356537593886/135Wx135H-.png)